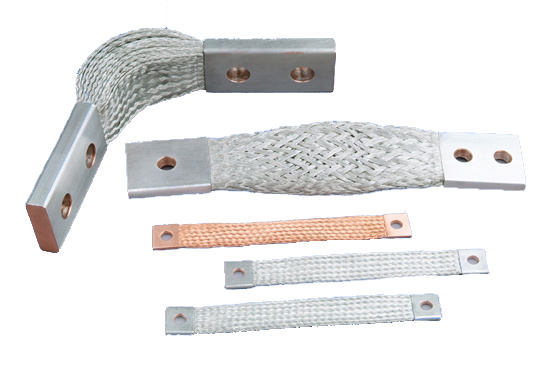

Soft connection

Welding soft connection is to press the laminated parts of copper strip (foil) together, adopt molecular diffusion welding, and form by high current heating and pressure welding

keywords:

classification:

Product display

hotline:

Soft connection

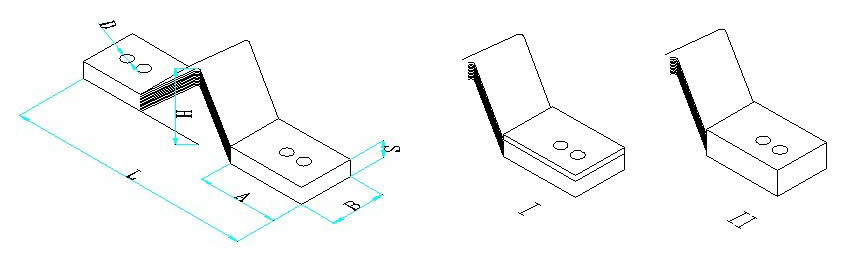

Strip copper connector made through press welding:

Press welding is to press the laminated portion of copper foils by molecular diffusion welding and high current heating.

Thickness of copper foil:0.03mm to 0.3mm.

The contact surface can be plated with tin or silver according to customer’s requirement.

Strip copper connector made through braze welding:

Braze welding is to press the laminated portion of copper foils and shape with flat copper block by silver-based brazing.

Thickness of copper foil:0.03mm to 0.3mm.

The contact surface can be plated with tin or silver according to customer’s requirement.

|

A (mm) |

B (mm) |

S (mm) |

L (mm) |

H (mm) |

Ection (mm2) |

Current-load(A) |

|

50 |

40 |

5 |

180 |

40 |

200 |

600 |

|

50 |

40 |

5 |

230 |

40 |

200 |

800 |

|

50 |

40 |

8 |

230 |

43 |

320 |

800 |

|

50 |

40 |

10 |

230 |

45 |

400 |

900 |

|

60 |

50 |

5 |

250 |

45 |

250 |

700 |

|

60 |

50 |

8 |

250 |

48 |

400 |

950 |

|

60 |

50 |

10 |

250 |

50 |

500 |

1100 |

|

90 |

60 |

8 |

300 |

70 |

480 |

1100 |

|

90 |

60 |

10 |

300 |

70 |

600 |

1200 |

|

90 |

80 |

8 |

300 |

70 |

640 |

1350 |

|

90 |

80 |

10 |

300 |

70 |

800 |

1500 |

|

90 |

80 |

12 |

300 |

70 |

960 |

1700 |

|

110 |

100 |

8 |

300 |

80 |

800 |

1550 |

|

110 |

100 |

10 |

350 |

80 |

1000 |

1800 |

|

110 |

100 |

12 |

350 |

80 |

1200 |

1900 |

|

130 |

120 |

10 |

400 |

80 |

1200 |

2000 |

|

130 |

120 |

12 |

400 |

80 |

1440 |

2200 |

Previous page

Next page

Previous page

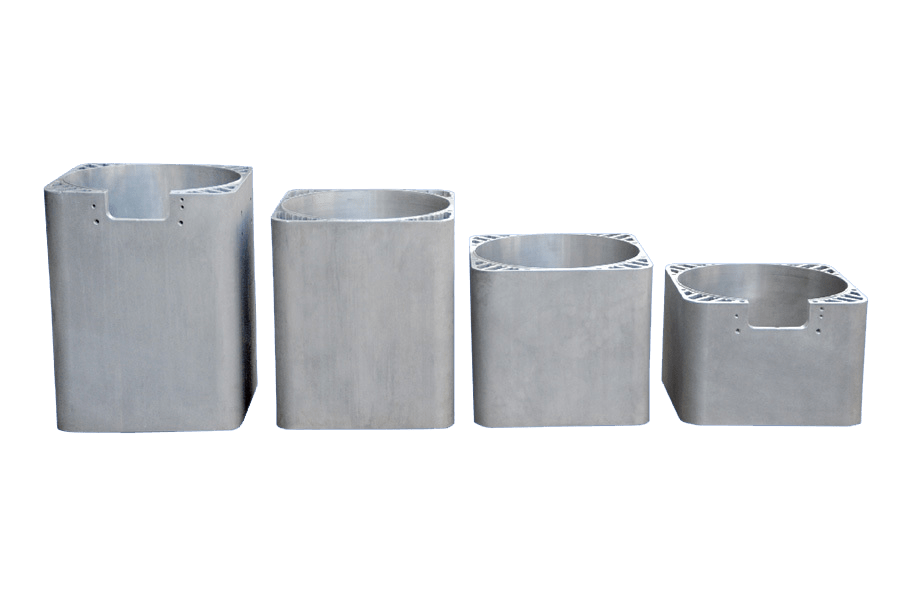

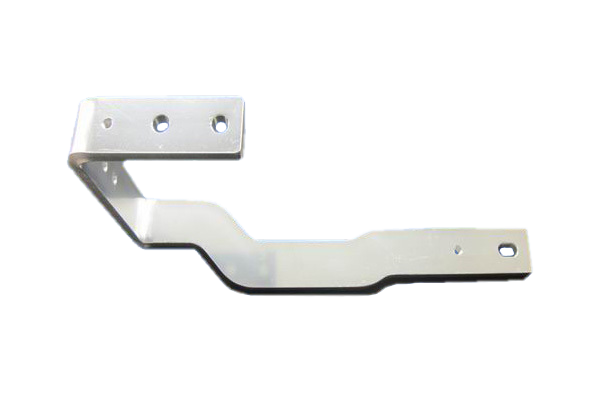

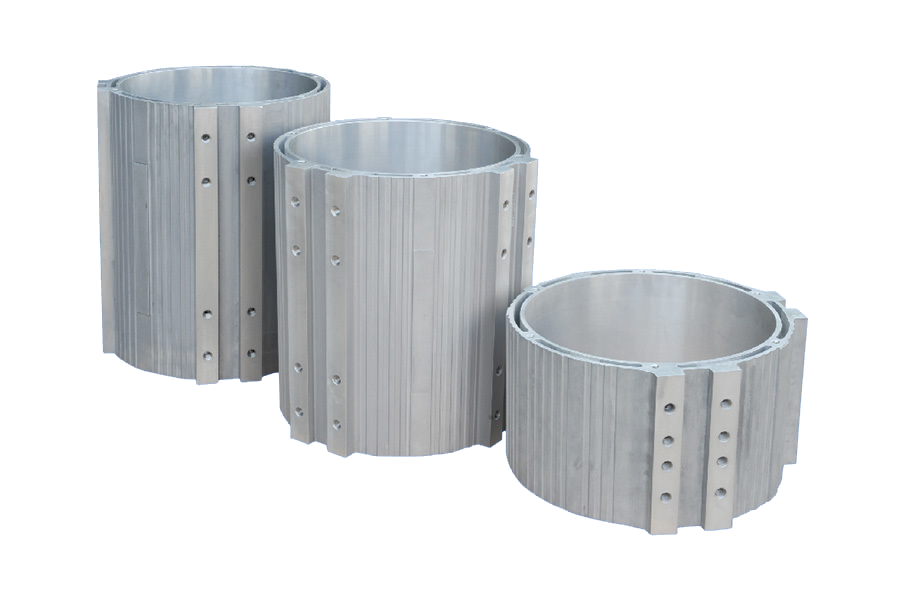

Radiator

Next page

Online message

* Note: Please be sure to fill in the information accurately and keep the communication open. We will get in touch with you as soon as possible