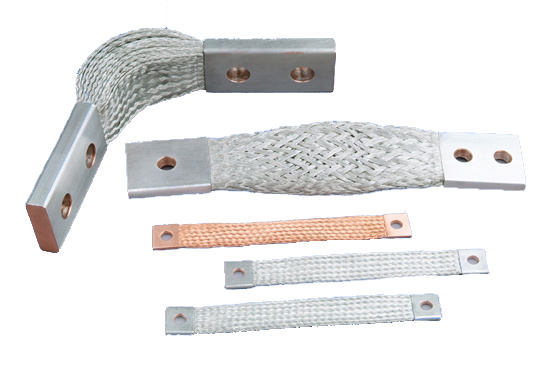

Insulated flexible copper bar

The insulated soft copper bar, also known as laminated insulated soft copper bar and flexible busbar, is made of multi-layer corona proof flat thin copper sheet conductors superimposed, and the outer layer is extruded to cover the insulating layer

keywords:

classification:

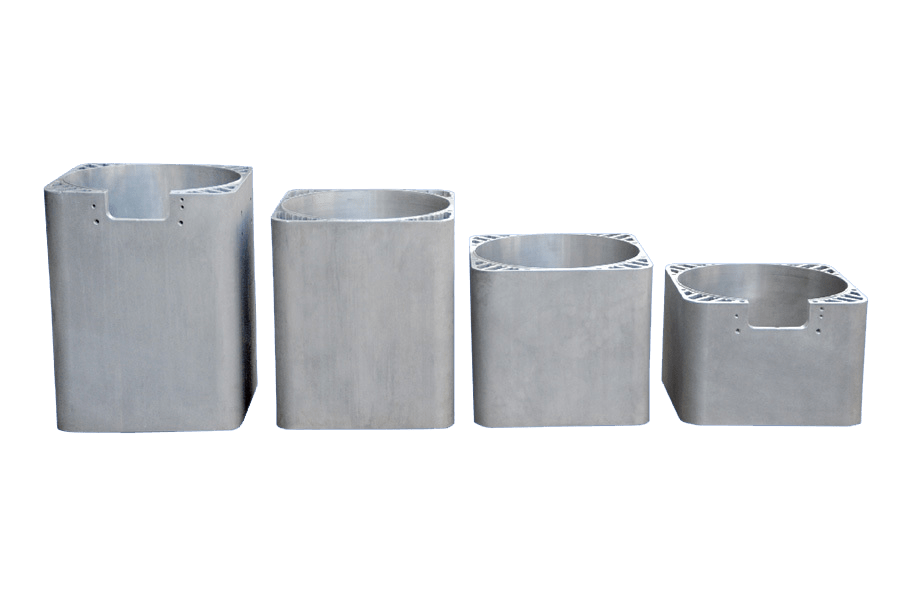

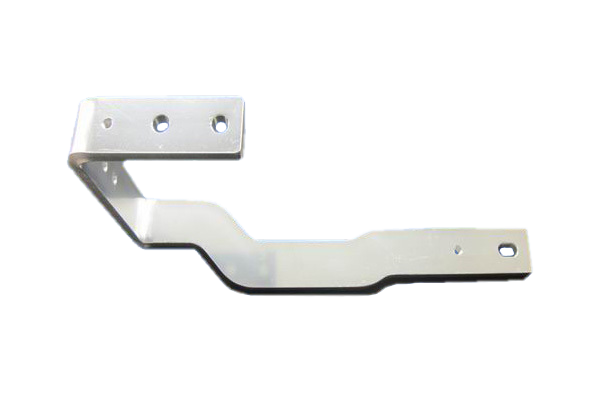

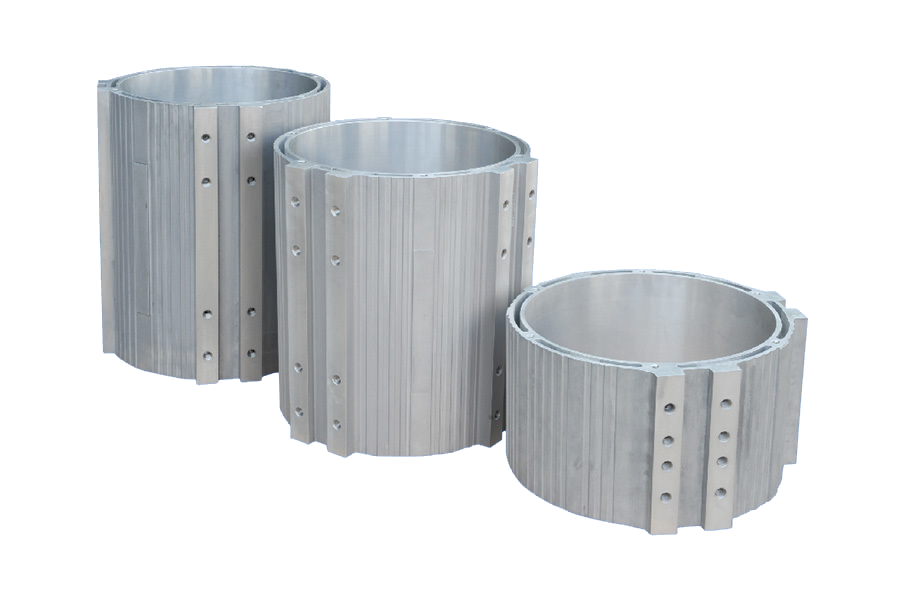

Product display

hotline:

Insulated flexible copper bar

1、Structural composition

1.Conductor

The conductor of insulated soft copper bar adopts T2 soft copper strip,which can be divided into bare copper and tinned copper.Copper strip specifications are 15.5×0.8,20×1,24×1,32×1,40×1,50×1,63×1,80×1,100×1.The number of laminations is 2 to 12.

2.Insulating layer

At present,the insulating layer of insulated soft copper bar has two materials:special polyvinyl chloride(PVC)and thermoplastic elastomer(TPE).TPE has the characteristics of low smoke and halogen-free.

2、Production standard

There is no special standard for insulated flexible copper bar in the world.The United States borrows UL758 electronic wire standard for production certification,and Xi'an Longyuan first began to manufacture it with reference to gb/t5023 insulated cable standard and UL758 electronic wire standard.

3、Product characteristics of insulated soft copper bar:

1.Easy to process and shape

Because the copper conductor can slide freely in the insulating layer,the insulating soft copper bar has infinite bending and torsion characteristics.The wide thickness ratio of copper strip varies greatly,which makes the flexible copper bar easy to bend in the thickness direction,but has high rigidity in the width direction,so that the insulated flexible copper bar can bend out any spatial configuration by hand or with simple tools,which is convenient for installation and wiring.

2.High current carrying capacity

Due to the skin effect,when passing through AC,the current inside the conductor is actually very small,and the current is concentrated in a thin layer near the outer surface of the conductor.The multilayer flat conductor structure of insulated soft copper bar makes the same conductor cross-sectional area can carry more passing current.Thus,the amount of conductor material is reduced,which not only reduces the weight,but also saves the layout space.

The following is a comparison of the required sections of insulated flexible copper bars and ordinary round cables under three current carrying capacities:

Current carrying capacity insulated soft copper bar sectional area circular cable sectional area

250A 40mm2 95mm2

630A 160mm2 300mm2

1000A 300mm2 555mm2

3.Convenient installation

After the insulating soft copper bar is bent and punched,the spatial shape of the structure can not only avoid the interference area,but also easily return to the original shape after bending during installation.The contact surface can be directly connected with the terminal and slightly fixed,eliminating the complex connection and fixation of traditional cables and busbar.

4、Application of insulated soft copper bar

Due to the excellent characteristics of insulated soft copper bar,it has become the first choice for electrical wiring.It will gradually replace the application of cable in electrical wiring,and the hard busbar of non main structure will also be gradually replaced by soft copper bar.

Technical parameters of soft copper bar conductor:

Annealed electrolytic copper:Cu%≥99.9%

Conductivity:≥56.2s/m

Vickers hardness:<50hv

Tensile strength:≥200MPa

Elongation:≥30%

Technical parameters of soft copper bar insulation layer:

PVC:PVC

Color:Black/orange

Coating method:extrusion molding

Dielectric strength:>23kv/mm

Oxygen index level:30%

Elongation after 135℃/7-day aging test:>180%

Tensile strength:>20MPa

Operating temperature:-30℃to+105℃

Flame retardant:self extinguishing

Working voltage range:750V(10531 line type)1000V(11343 line type)

Compressive strength:(15min/50hz):

To ground>15kV

Busbar room>30KV

Conductor type:bare copper strip/tinned copper strip

Standard length:2m or 3M

Standard product specification and allowable current:

|

Conductor size |

Section |

Current-load(A) |

Conductor size |

Section |

(A)Current-load |

||||

|

△T=20K(3) |

△T=40K(4) |

△T=50K(5) |

△T=20K(3) |

△T=40K(4) |

△T=50K(5) |

||||

|

15.5*0.8*2 |

24.8 |

125 |

175 |

200 |

40*1*2 |

80 |

240 |

330 |

380 |

|

15.5*0.8*3 |

37.2 |

160 |

210 |

240 |

40*1*3 |

120 |

330 |

480 |

540 |

|

15.5*0.8*4 |

49.6 |

195 |

265 |

295 |

40*1*4 |

160 |

400 |

560 |

630 |

|

15.5*0.8*6 |

74.4 |

225 |

320 |

360 |

40*1*5 |

200 |

450 |

630 |

710 |

|

15.5*0.8*8 |

99.2 |

265 |

380 |

430 |

40*1*6 |

240 |

480 |

680 |

750 |

|

15.5*0.8*10 |

124 |

300 |

420 |

480 |

40*1*8 |

320 |

600 |

830 |

920 |

|

20*1*2 |

40 |

170 |

240 |

270 |

40*1*10 |

400 |

670 |

920 |

1030 |

|

20*1*3 |

60 |

230 |

320 |

360 |

50*1*3 |

150 |

400 |

570 |

650 |

|

20*1*4 |

80 |

270 |

380 |

440 |

50*1*4 |

200 |

490 |

700 |

790 |

|

20*1*5 |

100 |

300 |

430 |

490 |

50*1*5 |

250 |

540 |

780 |

880 |

|

20*1*6 |

120 |

330 |

470 |

530 |

50*1*6 |

300 |

590 |

840 |

950 |

|

20*1*8 |

160 |

400 |

560 |

620 |

50*1*8 |

400 |

680 |

1000 |

1130 |

|

20*1*10 |

200 |

420 |

580 |

650 |

50*1*10 |

500 |

750 |

1100 |

1300 |

|

24*1*2 |

48 |

200 |

280 |

320 |

63*1*5 |

315 |

650 |

900 |

1000 |

|

24*1*3 |

72 |

250 |

360 |

410 |

63*1*6 |

378 |

690 |

980 |

1100 |

|

24*1*4 |

96 |

280 |

410 |

460 |

63*1*8 |

504 |

840 |

1200 |

1350 |

|

24*1*5 |

120 |

330 |

470 |

530 |

63*1*10 |

630 |

920 |

1300 |

1450 |

|

24*1*6 |

144 |

360 |

510 |

570 |

80*1*5 |

400 |

700 |

1100 |

1230 |

|

24*1*8 |

192 |

420 |

590 |

670 |

80*1*6 |

480 |

780 |

1210 |

1360 |

|

24*1*10 |

240 |

500 |

700 |

790 |

80*1*8 |

640 |

950 |

1400 |

1570 |

|

32*1*2 |

64 |

230 |

320 |

360 |

80*1*10 |

800 |

1090 |

1550 |

1730 |

|

32*1*3 |

96 |

280 |

410 |

460 |

100*1*5 |

500 |

860 |

1250 |

1400 |

|

32*1*4 |

128 |

320 |

460 |

520 |

100*1*6 |

600 |

950 |

1380 |

1530 |

|

32*1*5 |

160 |

390 |

550 |

610 |

100*1*8 |

800 |

1100 |

1580 |

1760 |

|

32*1*6 |

192 |

440 |

620 |

700 |

100*1*10 |

1000 |

1220 |

1710 |

1920 |

|

32*1*8 |

256 |

510 |

720 |

822 |

100*1*12 |

1200 |

1300 |

1800 |

2010 |

|

32*1*10 |

320 |

600 |

840 |

930 |

|

||||

The current carrying capacity of insulated flexible copper bar is related to the section size and temperature of flexible copper bar,as shown in the table above.The following factors should be considered in model selection:

① Current carrying capacity

② Allowable busbar temperature rise

③ Busbar width

The calculation formula of busbar temperature rise(△T)is as follows:

△T=Ta-Tc

TC:ambient temperature.

TA:the temperature of the soft copper bar after power on(important note:for general electrical equipment,Ta should be≤105℃).

Model selection examples(for reference only):

Requirements:the ambient temperature of the equipment is 40℃,the carrying capacity of the flexible copper bar is 510a,the maximum temperature on the flexible copper bar is not more than 100℃,and the width of the flexible copper bar is not more than 40mm.

Model selection:according to the formula,the maximum allowable temperature rise can be calculated as 60℃(100℃-40℃=60℃),so the specification can be selected as 32×one×4 flexible copper bar:the temperature rise of this specification of flexible copper bar under the load current of 520A is 50a,so this type selection is feasible and has sufficient safety margin.

UL758 certified(E336413)

CE certified

SGS certified:RoHS compliant

UL94 V-0

Operating temperature:-30℃to+105℃.

Operating voltage:600Vac/750Vdc;1000Vac/1500Vdc

Types available:max.width 120mm,max.thickness 12mm

Over 50 clients all over the world,especially in America

Two production lines

Strengths of insulated flexible Cu busbars compared with flexibles

A:Lead time:less processing procedure,shorter lead time,more suitable for mass production

B:Appearance properties:the insulated flexible Cu busbars do not need the process of high-temperature molecular welding,this can be avoided internal oxidation;Finished flexibles need electroplating,this may cause acid corrosion.

C:Flame resistance:the insulation flame retardant grade is UL94-V0,this is the highest flame resistance grade.But,welding flexible is setting heat-shrink tube on external,and the flame resistance grade of heat-shrink tube is VW-1.So,the insulated flexible Cu busbars are better than flexibles.

D:Cost analysis:to compared with flexibles,the process of flexibles is complex,and the cost of surface treatment is higher,while,due to the strict environmental requirements,all plating are centralized management in electroplating industrial district,so the distance is longer,and the cost of transportation is higher.However,for the flexible insulated bus bars,we only purchase the electroplated copper strip,and we what the process we only need to do is processing(bending),so the process is less,the delivery is faster,and the cost is lower.There exist some rejection rate for the flexibles,but Insulated flexible busbars can basically achieve 100%pass rate.

Previous page

Next page

Previous page

Water cooling plate

Next page

Online message

* Note: Please be sure to fill in the information accurately and keep the communication open. We will get in touch with you as soon as possible